Industrial Vacuums.

Providing

The Solution.

FINE DUST VACUUMING

Why use an industrial vacuum cleaner in your production?

A fine dust vacuum cleaner can be the ideal solution for cleaning and maintenance tasks in workplaces. A dry bagless vacuum cleaner offers many advantages:

INCREASED CLEANLINESS

By keeping the work environment clean, machinery and equipment can operate at peak efficiency, reducing downtime and increasing product quality.

INCREASED SAFETY

INCREASED PRODUCTIVITY

HOW TO CHOOSE A VACUUM CLEANER TO SUIT YOUR NEEDS

Several aspects must be considered when choosing an industrial vacuum cleaner for your production:

- The type of dust or material to be vacuumed: some vacuum cleaners are specific for particular types of dust, such as toxic or combustible dust. The type of filtration installed should be related to the particle size characteristics of the dust to ensure that cleaned air is returned to the work environment

- The function it will have to perform: should the industrial vacuum cleaner occasionally clean the work environment or work continuously on production lines? What does the material to be vacuumed look like?

- The size of the working area: the vacuum cleaner must be able to cover the entire area and operate in tight or narrow spaces if necessary. In the case of large rooms, dust management will be easier with the installation of a centralized vacuum system capable of conveying the material.

SUCTION UNIT

The power and airflow rate of the vacuum cleaner must be matched to the specific needs of the task to ensure adequate suction performance. Otherwise, the vacuum cleaner will not be able to do the job effectively and quickly.

FILTRATION IS AN ESSENTIAL ELEMENT

FILTER CLEANING SYSTEM

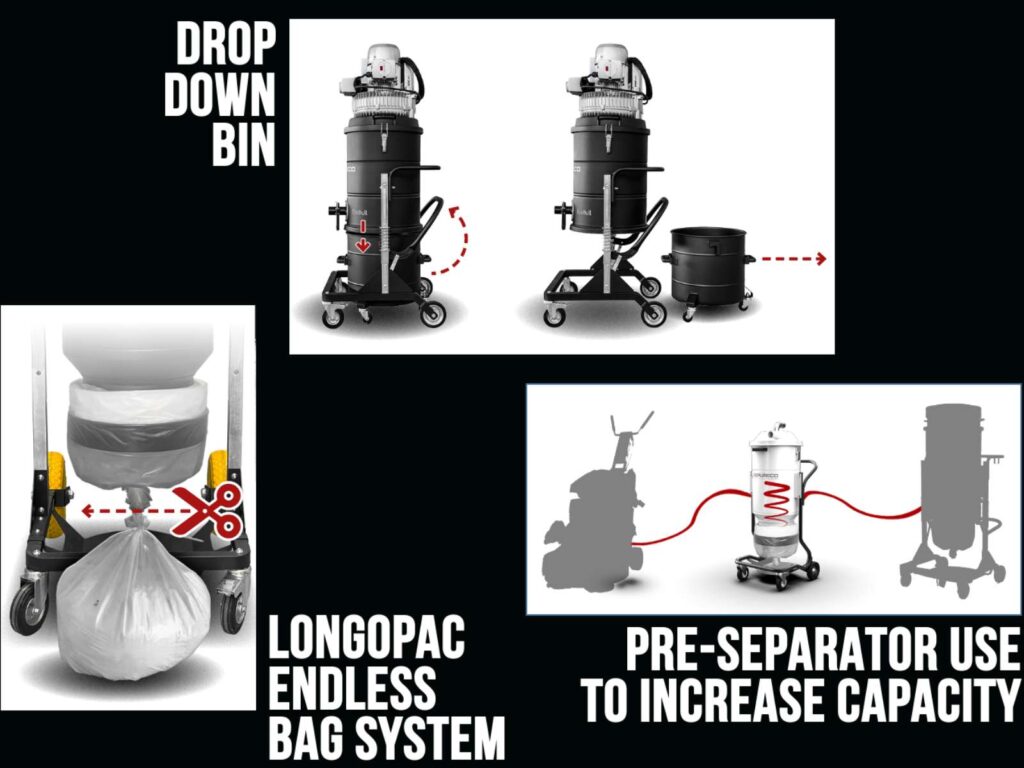

COLLECTION SYSTEM

Once vacuumed, the material can be collected in different ways in order to simplify disposal or recovery of the vacuumed material. It is possible to collect the material in containers or bag it directly for safe and easy disposal.