Industrial Vacuums.

Providing

The Solution.

Liquids Suction

Liquid presence problems and spills in industrial environments

The presence of liquids and spills in industrial environments can cause several problems:

- Accident risk: wet or slippery floors increase the risk of falls and accidents at work.

- Damage to machinery and equipment: corrosive or conductive liquids can damage electrical and mechanical components, causing malfunction and downtime.

- Product contamination: spills can contaminate products being processed, compromising quality and requiring cleanup or disposal.

Vacuum cleaners for liquids: how to choose the best one for your needs

FLOW RATE AND POWER

A vacuum generating unit that enables the vacuum function to be performed with the required speed and efficiency

TANK CAPACITY

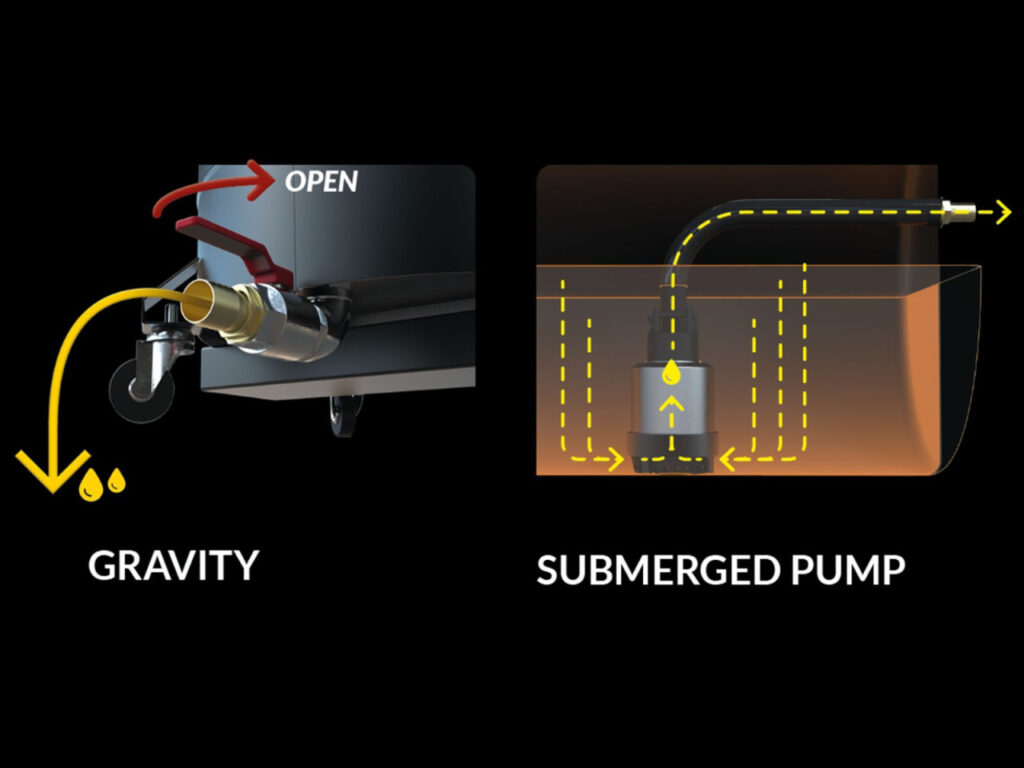

LIQUIDS DISCHARGE SYSTEM

Discharge via manual ball valve allows effortless emptying of the sucked-in liquid.

For more important and heavy-duty work, an immersed pump can be installed that will discharge the liquid automatically and quickly once the level set on the overflow sensor is reached, allowing simultaneous suction and discharge of the liquids!

SAFETY FLOATING DEVICE

The best liquid vacuum cleaners are equipped with safety systems in case the liquid level exceeds the maximum capacity limit.

A floating device will automatically stop the suction, preventing the vacuum from overflowing.

In addition to these features, it will also be essential to choose the appropriate flow rate and power to perform the function with the necessary speed and efficiency, as well as any additional filtration of the sucked liquids