MENUMENU

- MACHINES

-

-

- Floor Scrubber DryersOur floor scrubber dryer machines will scrub, clean and dry your floors in a single pass. From the most compact walk-behind machine for smaller areas to the largest ride on unit to clean larger floor areas in the quickest time possible, there is a model to suit every cleaning requirement.

- Walk Behind Floor Scrubber Dryers

- Ride On Floor Scrubber Dryers

- Floor SweepersSweepers Eliminate Workspace Dust. Our vacuum floor sweepers combine powerful dust extraction with high efficiency filtration to ensure that all dust is retained for disposal. Filters are cleaned automatically at the push of a button to ensure full suction at all times.

- Walk Behind Floor Sweepers

- Ride On Floor Sweepers

-

- Industrial Vacuum Cleaners

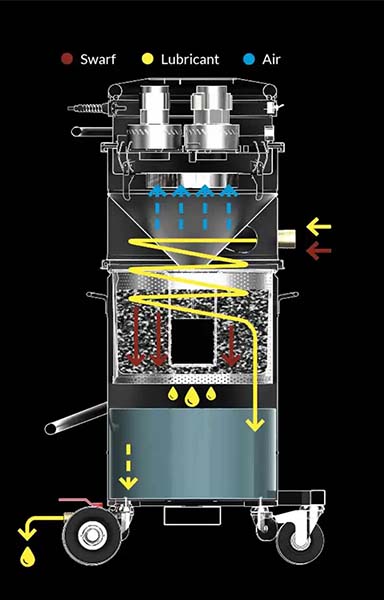

- Oil VacuumsIndustrial vacuums for oil & swarf

- ATEX VacuumsATEX Certified industrial vacuum cleaners

- Singlephase VacuumsSinglephase industrial vacuum cleaners

- Threephase VacuumsThreephase industrial vacuum cleaners

- MultiwashMultiwash roller brush multi surface floor cleaner range

-

-

- EX-HIRE & USED

-

-

- Used Scrubber DryersWhere applicable & unless otherwise stated All PTS Clean preowned machines are supplied complete with:- New batteries Fully service by PTS Clean engineers Operator instruction manual Parts manual Full technical support and training facilities Warranty

- Used Walk Behind Scrubber Dryers

- Used Ride On Scrubber Dryers

- Used SweepersWhere applicable & unless otherwise stated All PTS Clean preowned machines are supplied complete with:- New batteries Fully service by PTS Clean engineers Operator instruction manual Parts manual Full technical support and training facilities Warranty

- Used Walk Behind Sweepers

- Used Ride On Sweepers

-

-

- HIRE

- INDUSTRIES

- SUPPORT

- ABOUT

- CONTACT

MENUMENU

- MACHINES

-

-

- Floor Scrubber DryersOur floor scrubber dryer machines will scrub, clean and dry your floors in a single pass. From the most compact walk-behind machine for smaller areas to the largest ride on unit to clean larger floor areas in the quickest time possible, there is a model to suit every cleaning requirement.

- Walk Behind Floor Scrubber Dryers

- Ride On Floor Scrubber Dryers

- Floor SweepersSweepers Eliminate Workspace Dust. Our vacuum floor sweepers combine powerful dust extraction with high efficiency filtration to ensure that all dust is retained for disposal. Filters are cleaned automatically at the push of a button to ensure full suction at all times.

- Walk Behind Floor Sweepers

- Ride On Floor Sweepers

-

- Industrial Vacuum Cleaners

- Oil VacuumsIndustrial vacuums for oil & swarf

- ATEX VacuumsATEX Certified industrial vacuum cleaners

- Singlephase VacuumsSinglephase industrial vacuum cleaners

- Threephase VacuumsThreephase industrial vacuum cleaners

- MultiwashMultiwash roller brush multi surface floor cleaner range

-

-

- EX-HIRE & USED

-

-

- Used Scrubber DryersWhere applicable & unless otherwise stated All PTS Clean preowned machines are supplied complete with:- New batteries Fully service by PTS Clean engineers Operator instruction manual Parts manual Full technical support and training facilities Warranty

- Used Walk Behind Scrubber Dryers

- Used Ride On Scrubber Dryers

- Used SweepersWhere applicable & unless otherwise stated All PTS Clean preowned machines are supplied complete with:- New batteries Fully service by PTS Clean engineers Operator instruction manual Parts manual Full technical support and training facilities Warranty

- Used Walk Behind Sweepers

- Used Ride On Sweepers

-

-

- HIRE

- INDUSTRIES

- SUPPORT

- ABOUT

- CONTACT

PTS Clean Ltd. 3 Thomson Court, Rutherglen, Glasgow G73 2RR. Tel: 0141 647 4200 | Email: info@ptsclean.com

Connect With PTS Clean

The Cleaning Machine People.

Tel: 0141 647 4200

Email: info@ptsclean.com

Get our latest news & offers straight to your inbox

Copyright 2024 PTS Clean Ltd. Website Design and Development by Adeo Group.